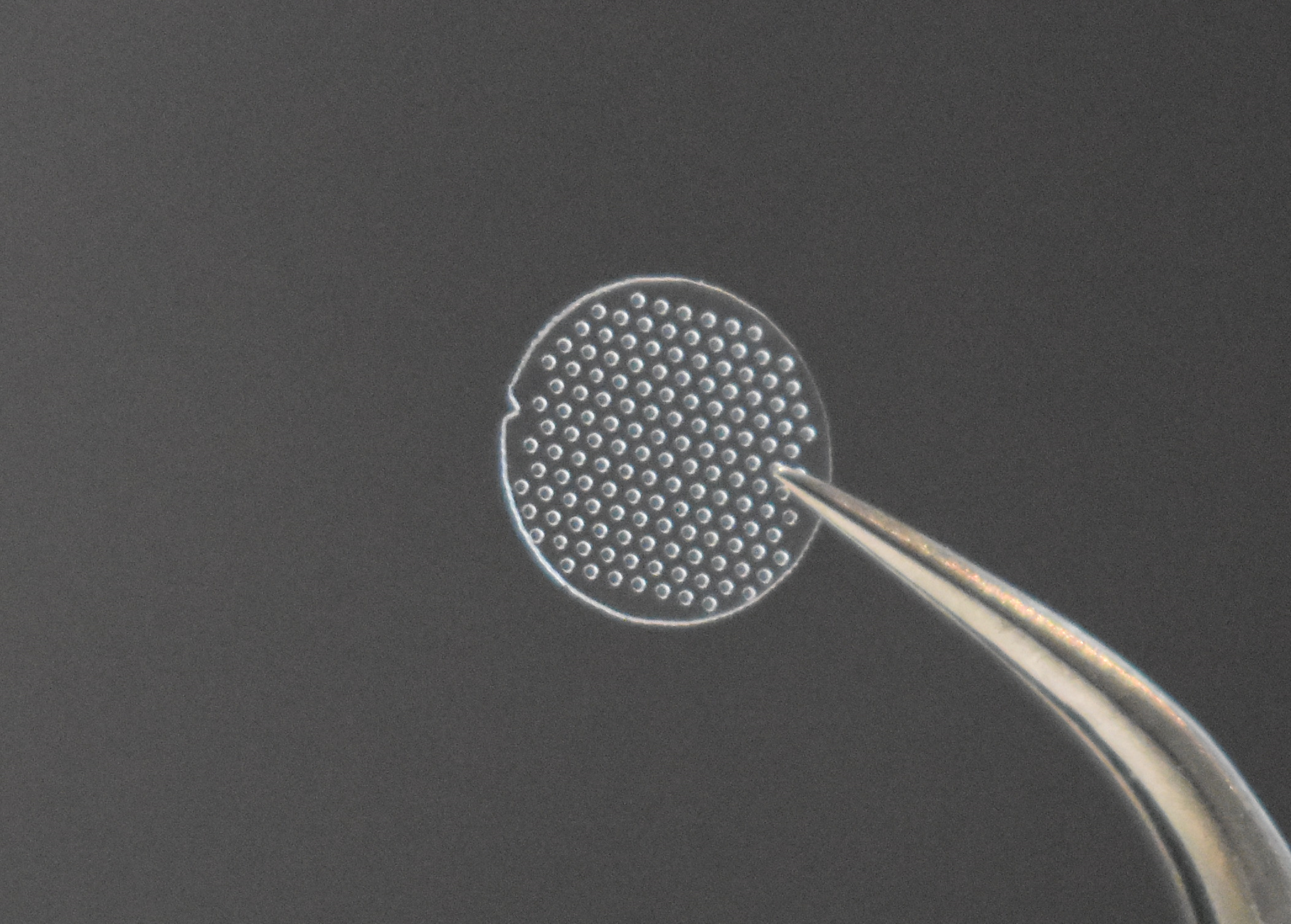

The micromesh arrays contain circular or square hole arrays through a thin polymer membrane that can be used to create nano litre wells and are a perfect solution for dynamic live cell imaging and analysis. The mesh format enables the micromesh arrays to be used with cell culture ware that contains biologically treated surfaces resulting in a micro-well with an active base and hydrophobic walls.

The microstructured mesh of the micromesh arrays enable biologists to confine sub-populations of cells for long term imaging, screening and analysis and can be used in conventional cell culture ware reducing the need to design new experiments.

In addition the through holes in the micromesh arrays are perfect as a micro stencil for producing micropatterned protein arrays.

The size and shape of the micromesh arrays enable high, medium and low resolution imaging of cells over extended periods of time ranging from hours to days.

The advantage

Compatible with an extensive range of culture ware

Suitable for fluorescence, transmission and DIC imaging

No glue or adhesive required

No change to standard workflow

Increased data collection efficiency

Achieve long term live cell imaging

The micromesh arrays are circular inserts manufactured from a bio-compatible silicone polymer. The arrays are self-adherent and will stick to any glass or polymer surface based cell culture ware or imaging chamber.

| Product code | Size (μm) | Depth (μm) | Well shape | Bottom profile | Array shape | Array size (mm) | Wells per array | Arrays per pack | Price per pack (AUD$) | MOQ |

|---|---|---|---|---|---|---|---|---|---|---|

| MMA-0075-08-01 | 75 | 100 | Circle | N/A | Circle | 8 | 145 | 10 | $250.00 | 1 |

| MMA-0075-15-01 | 75 | 100 | Circle | N/A | Circle | 15 | 532 | 3 | $110.00 | 2 |

| MMA-0075-30-01 | 75 | 100 | Circle | N/A | Circle | 30 | 2,245 | 1 | $80.00 | 4 |

| MMA-0100-08-01 | 100 | 100 | Circle | N/A | Circle | 8 | 145 | 10 | $225.00 | 1 |

| MMA-0100-15-01 | 100 | 100 | Circle | N/A | Circle | 15 | 532 | 3 | $100.00 | 2 |

| MMA-0100-30-01 | 100 | 100 | Circle | N/A | Circle | 30 | 2,245 | 1 | $75.00 | 4 |

| MMA-0150-08-01 | 150 | 100 | Circle | N/A | Circle | 8 | 145 | 10 | $225.00 | 1 |

| MMA-0150-15-01 | 150 | 100 | Circle | N/A | Circle | 15 | 532 | 3 | $100.00 | 2 |

| MMA-0150-30-01 | 150 | 100 | Circle | N/A | Circle | 30 | 2,245 | 1 | $75.00 | 4 |

| MMA-0250-08-01 | 250 | 100 | Circle | N/A | Circle | 8 | 145 | 10 | $225.00 | 1 |

| MMA-0250-15-01 | 250 | 100 | Circle | N/A | Circle | 15 | 532 | 3 | $100.00 | 2 |

| MMA-0250-30-01 | 250 | 100 | Circle | N/A | Circle | 30 | 2,245 | 1 | $75.00 | 4 |

| MMA-0500-08-01 | 500 | 100 | Square | N/A | Circle | 8 | 34 | 10 | $225.00 | 1 |

| MMA-0500-15-01 | 500 | 100 | Square | N/A | Circle | 15 | 129 | 3 | $100.00 | 2 |

| MMA-0500-30-01 | 500 | 100 | Square | N/A | Circle | 30 | 583 | 1 | $75.00 | 4 |

| MMA-0750-08-01 | 750 | 100 | Square | N/A | Circle | 8 | 16 | 10 | $225.00 | 1 |

| MMA-0750-15-01 | 750 | 100 | Square | N/A | Circle | 15 | 74 | 3 | $100.00 | 2 |

| MMA-0750-30-01 | 750 | 100 | Square | N/A | Circle | 30 | 349 | 1 | $75.00 | 4 |

| MMA-1000-08-01 | 1000 | 100 | Square | N/A | Circle | 8 | 9 | 10 | $225.00 | 1 |

| MMA-1000-15-01 | 1000 | 100 | Square | N/A | Circle | 15 | 46 | 3 | $100.00 | 2 |

| MMA-1000-30-01 | 1000 | 100 | Square | N/A | Circle | 30 | 226 | 1 | $75.00 | 4 |

Product specifications published on the website may be subject to change without notice.

If you cant find what you are looking for then please have a look at our Custom products page as we offer custom manufacture, or alternatively email us at sales@microsurfaces.com.au to discuss your requirements.

The product code refers to the packaged product which contains 1, 3 or 10 individual arrays. All prices shown are in AUD$ and do not include GST (for Australian orders) or VAT (for European orders). For Australian orders the GST will be confirmed during quotation/ordering and for European orders VAT is payable by the customer. Pricing in Euros and US$ can be provided. Prices do not include postage. All international orders will be shipped by Fedex and freight costs will be confirmed during ordering.

MOQ = Minimum Order Quantity.

The micromesh arrays are sterilsed in alcohol prior to shipping. Prior to use they may be sterilized in alcohol, UV or by autoclaving.

The micromesh arrays are NOT manufactured with registration marks as the entire surface area of the array is covered in wells.

For the micromesh arrays with well sizes <500μm the holes are conical in shape. For the micromesh arrays with well sizes >500μm the holes are cylindrical in shape. The well size is determined by the smaller hole at the bottom surface of the array. Variation in the diameter of the hole is ±10 μm.

High content imaging and analysis

Single cell imaging

Dynamic live cell imaging and analysis

Cell tracking

Imaging cell-cell interactions

Cell proliferation and lineage trees

Immunofluorescence

FRET imaging

Protein patterning

User guides

Instructions for using microcell arrays

1. Using a pair of tweezers lift the edge of the microcell array to peel the insert off the carrier slide. Always use gloves when working with the microcell arrays as contamination (e.g. dust, oils,...) from the skin can adversely affect the adhesive performance of the arrays.

2. Carefully place the microcell array into the imaging culture ware by laying the insert down from one edge to ensure that no air is trapped between the surface of the culture ware and the microcell array. If air bubbles become trapped, then remove the insert and try again. If the trapping of air bubbles continues, place one to two drops of ethanol onto the culture ware, then lay the insert down. Please note, if you use ethanol to assist in laying the insert down, leave the culture ware in the hood for at least 60 minutes to allow the ethanol to evaporate, otherwise the insert will not stick to the cell culture ware when the media is added.

NOTE: To check for trapped air bubbles under the array turn the culture ware upside down and look through the bottom surface.

3. The microcell array inserts are provided in vacuum sealed packaging; however, we recommend the following step for sterilization. Pipette 70 - 100% ethanol on top of the microcell array until the bottom surface of the culture ware including the insert is covered. Use a 1,000 μL pipette to cycle the ethanol in the culture ware in order to assist in removing any air bubbles that may be trapped in the wells. Finally use the pipette to draw out almost all the ethanol from the culture ware making sure that the array is always covered in liquid, and discard as waste.

NOTE: The microcell arrays are very hydrophobic and the addition of warm media to the arrays if they ethanol rinse is completely aspirated will result in air bubbles being trapped in the wells.

4. Slowly add warm media to one corner of the culture ware until almost full.

5. Draw out the media/ethanol mixture from the opposite corner of the culture ware, taking care that the microcell array is always covered with liquid.

6. Repeat steps 4 and 5 at least five times to make sure the ethanol is completely diluted out.

7. Pipette cells into the culture ware directly above the array. For a typical imaging experiment, seed between 1 - 2x104 cells. Allow approximately 30 mins for the cells to settle before imaging.

Do the microcell arrays require adhesive?

No, the arrays are self-adhesive and will stick to polymer or glass surfaces.

Are the microcell arrays re-usable?

While it is possible to re-use the arrays we strongly discourage re-using the arrays. Small molecules and proteins can adsorb onto the polymer surface which can affect subsequent imaging experiments.

Can cells move between the wells in the microcell arrays?

Under normal conditions cells are not able to migrate between the wells. If a surface coating is applied to the array then it is possible for cells to migrate out of the wells.

Is it possible to perform independent experiments in the wells in a microcell array?

It is possible to perform independent experiments in individual wells by placing a lid on the top of the array to seal the individual wells. Once the cells have been introduced into the wells a glass coverslip can be used to seal the array. Gently press the coverslip onto the array using your finger to ensure that it is sealed against the array and squeezed out any excess media.

Which solvents and chemicals are compatible with the microcell arrays?

Below is a list of solvents and their compatibility with the microcell arrays. Please note that solvents with a high swelling ratio will likely cause the array to swell and detach from the surface of the imaging chamber.

| Solvent | Compatible | Swelling ratio |

|---|---|---|

| Acetone | Yes | 1.06 |

| Acetonitrile | Yes | 1.01 |

| Chloroform | Yes | 1.39 |

| Dimethyl sulfoxide (DMSO) | Yes | 1.00 |

| Ethanol | Yes | 1.04 |

| Hexane | Yes | 1.35 |

| Iso-propanol | Yes | 1.09 |

| Methanol | Yes | 1.02 |

| Water | Yes | 1.00 |

What material are the microcell arrays made from?

The clear microcell arrays are manufactured in polydimethylsiloxane (PDMS), Sylgard 184 from Dow.

Is polydimethylsiloxane (PDMS) biocompatible?

Polydimethylsiloxane (PDMS) has been demonstrated to be a biocompatible polymer for use in imaging and culturing many types of mammmalian cells. It is one of the most common materials used in the production of microfluidic devices.

Which microcell array would you recommend for use with a high magnifaction objective?

For imaging experiments with an objective lens with a magnifcation of >60x then the micromesh arrays are the only suitable product. The wells in the micromesh arrays are complete through holes so the cells will be seeded onto the surface of the coverslip. The imaging experiments with a medium or low magnification objective (e.g. <40x) any of the products are suitable.

What products can the microcell arrays be used with?

The microcell arrays can be used with any standard cell culture ware or imaging chamber with polymer or glass surfaces. The following list provides examples of the typical products used with the microcell arrays for imaging experiments.

35mm dish - Ibidi, Mattek, Wellco

Chamber slides - Ibidi, Mattek, Nunc, MerckMillipore, ThermoFisher Scientific

Multiwell plates (96, 48, 24, 12, 6) - Ibidi, Nunc, MerckMillipore, ThermoFisher Scientific

Do the microcell arrays produce fluorescence?

Under normal fluorescence microscyop conditions there will not be any fluorescence detected from the microcell arrays. When imaging cell autofluorescence the high laser power has been shown to generate autofluorescence in the standard clear polymer used for the arrays. If you are planning autofluorescence based experiments please contact us to discuss the micromesh arrays in a black polymer. It is not possible to offer microgrid, microwell arrays in the black polymer.

What is the shelf life of the microcell arrays?

The shelf life of the microcell arrays is 6 months. While the polymer used to manufacture the arrays does not degrade over time the self-adhesive ability of the array does reduce. It is possible to still use the arrays after 12 months assuming they are stored appropriately. If you are experiencing issues with the arrays not sticking to a surface have a look at the information listed under 'Tips & tricks' on the Instructions page.

How should the microcell arrays be stored?

The microcell arrays are shipped in a plastic container inside a vacuum sealed bag. Any unused arrays should be kept in the plastic container and vacuum bag (not under vacuum). The arrays can be stored at room temperature.

Please contact your local distributor or contact us directly at sales@microsurfaces.com.au to discuss your application and requirements.